In the fast-paced world of sheet metal fabrication, precision, speed, and efficiency are non-negotiable. As demand grows for custom parts and shorter lead times, manufacturers are turning to design automation to gain a competitive edge. One particularly powerful method is integrating Excel with AutoCAD through plugins — a combination that allows dynamic and parametric CAD drawing generation with minimal manual intervention.

This case study explores how a mid-sized sheet metal fabrication company transformed its design-to-manufacturing pipeline by automating drawing generation using an Excel-to-AutoCAD plugin.

The Challenge: Manual Drafting Bottlenecks

Our subject, a 150-employee sheet metal company, specialized in producing custom HVAC ducts, enclosures, and brackets. The design team faced several challenges:

Repetitive Drawing Tasks: Engineers repeatedly created similar drawings with minor variations for custom orders.

Human Errors: Manual entry of dimensions and parameters often led to mistakes, causing delays and rework.

Slow Turnaround: Each drawing could take 30–45 minutes, even for small changes.

Inefficient Workflows: The disconnect between sales, design, and production created delays in communication and increased lead times.

The team needed a solution that could reduce design time, eliminate errors, and streamline the path from order to production.

The Solution: Excel to AutoCAD Plugin for Design Automation

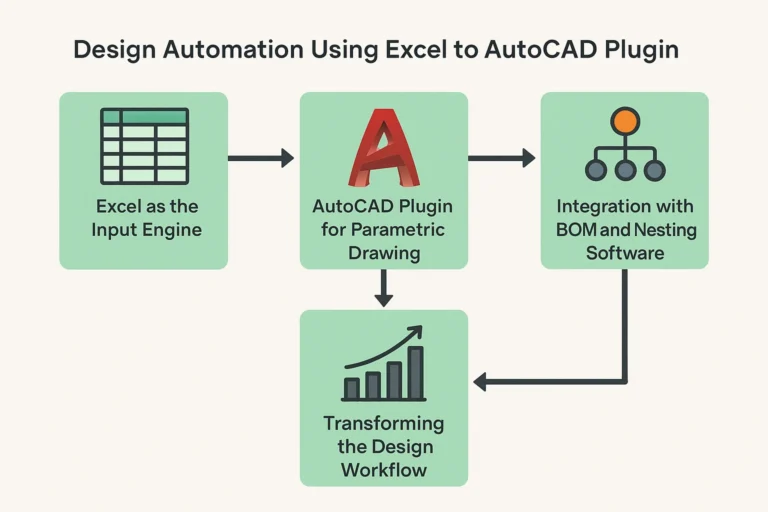

The company implemented a design automation system using a custom Excel to AutoCAD plugin. Here’s how it worked:

1. Excel as the Input Engine

The company built a dynamic Excel spreadsheet containing:

Fields for part parameters (length, width, gauge, bend radius, hole pattern, etc.)

Dropdowns for standard sizes and materials

Formulas to calculate flat patterns and developable geometry

Logical checks to prevent invalid input

Sales and engineering teams could now fill out this sheet with customer requirements, avoiding repetitive data entry.

2. AutoCAD Plugin for Parametric Drawing

A custom AutoCAD plugin (using AutoLISP or .NET) was developed to:

Read the parameter values directly from the Excel sheet

Auto-generate accurate 2D flat patterns and 3D models in AutoCAD

Apply standard layers, annotations, and dimensioning styles

Automatically export the drawing as DXF for CNC cutting

3. Integration with BOM and Nesting Software

The plugin was also integrated with downstream processes:

Bill of Materials (BOM) generation in Excel

Direct import into nesting software for laser cutting or punching machines

Integration with ERP for scheduling and costing

The Impact: Transforming the Design Workflow

The results were impressive:

| Metric | Before Automation | After Automation |

|---|---|---|

| Drawing Time | 30–45 minutes | 2–5 minutes |

| Errors Per Week | 4–5 | <1 |

| Orders Processed/Day | 10–12 | 30–35 |

| Design Team Size | 5 | 3 (redeployed others to R&D) |

| Lead Time | 3–4 days | 1–2 days |

Benefits Realized

Speed: Drastically reduced drawing creation time.

Consistency: Standardized drawings with uniform quality and formats.

Flexibility: Quickly respond to custom orders by simply updating Excel inputs.

Scalability: New product variants could be created without touching CAD manually.

Error Reduction: Automated logic prevented invalid inputs and costly mistakes.

Key Takeaways

Excel to AutoCAD automation is a low-cost, high-impact solution, especially for repetitive, parameter-driven design tasks.

Sheet metal companies can use this approach to accelerate product development, improve quality, and reduce labor costs.

The automation also promotes better collaboration between sales, engineering, and production by centralizing inputs and outputs.

Conclusion

Design automation isn’t just for massive corporations with enterprise software budgets. This case study demonstrates how even a mid-sized sheet metal fabrication company can harness the power of Excel and AutoCAD plugins to automate processes, minimize errors, and significantly boost productivity.

As the industry moves toward digital manufacturing and Industry 4.0, solutions like this aren’t just helpful — they’re essential.